CRPE3250

Robotic cell for grinding and polishing tubular car components.Products: bumpers, running boards, fenders, beams, guards, etc.

Material: stainless steel, carbon steel, aluminium.

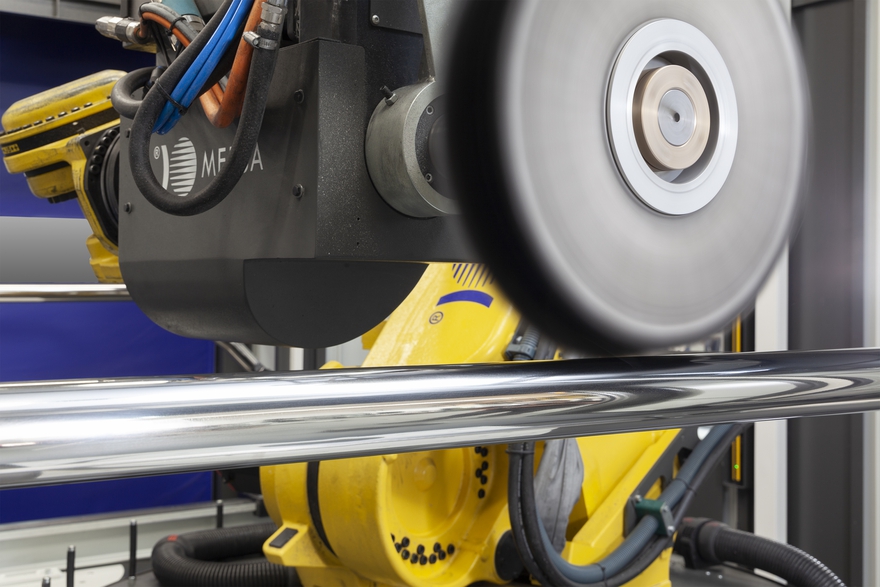

Processes: grinding, polishing and brightening.

Two independent stations at 180º. Robot in central position with linear movement “linear track system”.

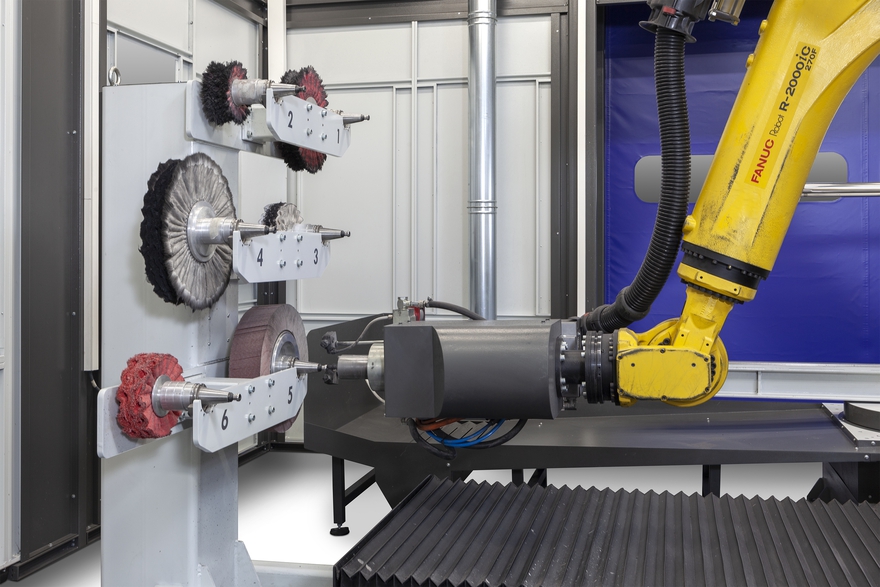

Integration of several robot brands: ABB, FANUC, KUKA, YASKAWA, etc.

Automatic change of grinding and polishing wheels.

Multiple applications: machining, deburring, grinding, polishing, satin...

Automated system for pressure control, wear compensation and mops tangential speed maintenance.

High adaptability: possibility to process a wide variety of complex geometries.

Customised HMI. Easy adjustment and real-time control of production parameters.

Optional: MEPSA connect4.0Industry 4.0. Remote real-time control of production.

MEPSA online service. Remote assitance.

Offline programming available as an option.

Highlights

VERSATILITY

Two station. Working cycle without interruptions. Customised configuration adapted to customer needs.

POLYVALENT

Possibility to process different parts in each station. Alternating working cycle. Customised layout to process a wide variety of parts of large dimensions.

AUTOMATIC QUICK CHANGE OF MOPS

Station with store for six mops of different types and dimensions.

SURFACE FINISH QUALITY

Guaranteed homogeneous polishing without deformation of 100% of the surface. Process repeatability. Constant production.

CUSTOMISED HMI SOFTWARE

Intuitive and easy to use. Remote assitance.

MEPSA CONNECT 4.0

Remote real-time control of production. Production parameters monitoring and cell efficiency. Access to cell and data collection from any location. Warning system and notifications by SMS, PUSH and WhatsApp.

Contact request

You can contact us through a message using the form that you will find below.